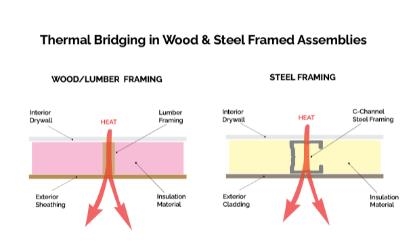

Timber frame construction is becoming more and more popular as a terrific way to build homes that are good for the environment and save energy. This is because it combines the natural insulating characteristics of wood and precisely placed thermal breaks to keep heat inside. The microscopic air pockets in wood’s cellular structure inherently slow down the flow of heat. This means that wood is a much better material for reducing thermal bridging, which is the main method that energy is lost and electricity bills go up.

Builders make a barrier that blocks undesired heat from flowing by putting continuous insulation and exact thermal breaks right into the wood frames. This is similar to how a coffee cup sleeve works. This keeps the temperature inside steady even when the weather changes. This strategy not only meets but often goes beyond and beyond strict standards like Passivhaus and Part L in the UK. It makes homes that stay warm in the winter and cool in the summer while consuming a lot less energy.

The science behind it is really cool. Studies reveal that thermal bridging between framing members can cause up to 30% of heat loss in walls made of wood. Adding a thermal break with an R-value of only 0.2 can make wall insulation work more than 80% better overall. A break with an R-value of 0.4 can practically quadruple the insulation’s effectiveness, making it work more like metal frame. These adjustments mean that homes need a lot less heating and cooling, which decreases their carbon footprints and saves homeowners actual money on their energy costs.

Sustainability advocates and leaders in the industry stress timber not only for its insulating capabilities, but also because it is a renewable resource that stores carbon and supports biodiversity, which is in accordance with the goals of a circular economy. It’s apparent that the future is in using the best thermal break technology with the natural benefits of wood. These two items work together to protect comfort, health, and the environment by lowering operational emissions.

To make this shift even bigger, consider about these really imaginative and useful ideas to make the energy consumption of timber frames better:

a. Use stiff foam or mineral wool panels as continuous exterior insulation to form a thermal barrier that goes all the way around the frame without any breaks.

b. Use insulation that is built into the factory in prefabricated wood panels to cut down on gaps and make sure the building is airtight.

b. To take use of natural heat and keep the house from getting too hot, employ passive solar design concepts like positioning windows in the proper positions and shading them.

d. Use new framing strategies that lower the framing factor. This will minimize the quantity of wood that lets heat through and raise the overall insulation.

e. Follow new building codes and incentives that say you have to incorporate thermal breaks to stop the effects of thermal bridging.

f. To gain even more benefits, get wood from places that are excellent for the environment and save energy.

The revolution in timber frame building proves without a doubt that attractive buildings and high energy efficiency can go hand in hand. The wonderful combination of timber’s natural insulation and more advanced thermal breaks makes a plan for heating homes—and hearts—more intelligently and sustainably in the years to come that is scalable, elegant, and practical.