In custom joinery, CNC (Computer Numerical Control) precision is a great mix of machine accuracy and skilled craftsmanship. This combination changes how custom woodwork is designed, created, and enjoyed by bringing together the mechanical perfection of machines with the delicate art of human hands.

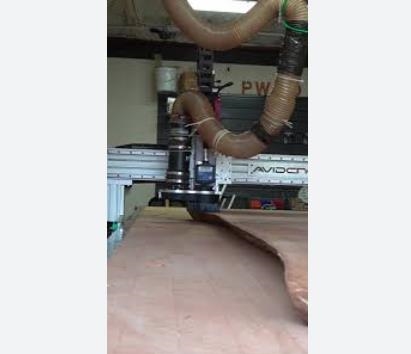

In the past, professional artisans with steady hands and trained eyes were needed for bespoke joinery. CNC routers can now manufacture designs with an accuracy of *thousandths of an inch.* They can easily make sophisticated dovetails, mortise and tenon joints, and patterns. This incredible accuracy stops mistakes that occurs when people aren’t consistent, so every assembly fits right every time. The result is a greater quality that helps craftspeople explore creative complexity while still preserving the unique look that comes from handcrafting.

CNC technology makes things run a lot better in business. Machines work rapidly and all the time, which increases output and cuts down on scrap and waste. This method is *very efficient* and lowers costs without losing uniqueness. It also makes it easier and cheaper for custom makers to construct intricate or recurring designs, like custom kitchens or fitted closets. The first cost of CNC technology quickly pays off by cutting labor costs and increasing output, which makes high-quality bespoke joinery affordable to more individuals.

CNC precision is vital since it doesn’t replace the craftsman; it makes their work better. It is nevertheless vital to have expert joiners put the pieces together and provide the finishing touches that make each one unique and charming. This mix of machine elements that are cut properly and polished by hand gives works that are both technically perfect and deeply touching.

CNC is not only precise and quick, but it also provides you a lot of creative freedom. It lets you add delicate inlays, fine engravings, and bespoke patterns with repeatable accuracy—things that were too hard or time-consuming to achieve by hand. Now, artisans can take enormous concepts and make them into genuine, exquisite works of art that go beyond what anyone thought was possible.

For example, Urban Bespoke Interiors uses modern 5-axis CNC gear to show how this mix of digital precision and traditional craftsmanship can make beautiful, long-lasting interiors faster and for less money. People who work in the industry say that CNC changes productivity, accuracy, and scalability, which makes custom joinery not just faster but also easier for customers to receive.

The following are the benefits of choosing custom joinery with CNC technology:

– **Unmatched accuracy**: Parts are cut to the exact millimeter size so that they fit and line up flawlessly.

– Much better efficiency: Businesses may grow without losing quality since they make things faster and waste less material.

– **Incredibly improved creative potential**: the ability to construct complex, one-of-a-kind things over and over again with accuracy.

– **Custom solutions that are unexpectedly cheap**: The project costs less overall since labor and materials are cheaper.

– Always great safety and quality: The workshop is safe and dependable since it has built-in safety precautions and automatic quality checks.

In the future, CNC precision will be a cool combination of old and new in custom woodwork. Machine accuracy will make the craft better, not worse. Each piece is carved just perfectly, conveying a story of balanced creativity that defines a future where “accuracy beautifully meets craftsmanship.” People who enjoy bespoke woodworking can do a lot more with CNC technology than they could before. This is the start of a new era of high-quality custom work.